Add Fire Suppression Systems

Spark Detection & Extinguishing System

THE FLAMEX SYSTEM

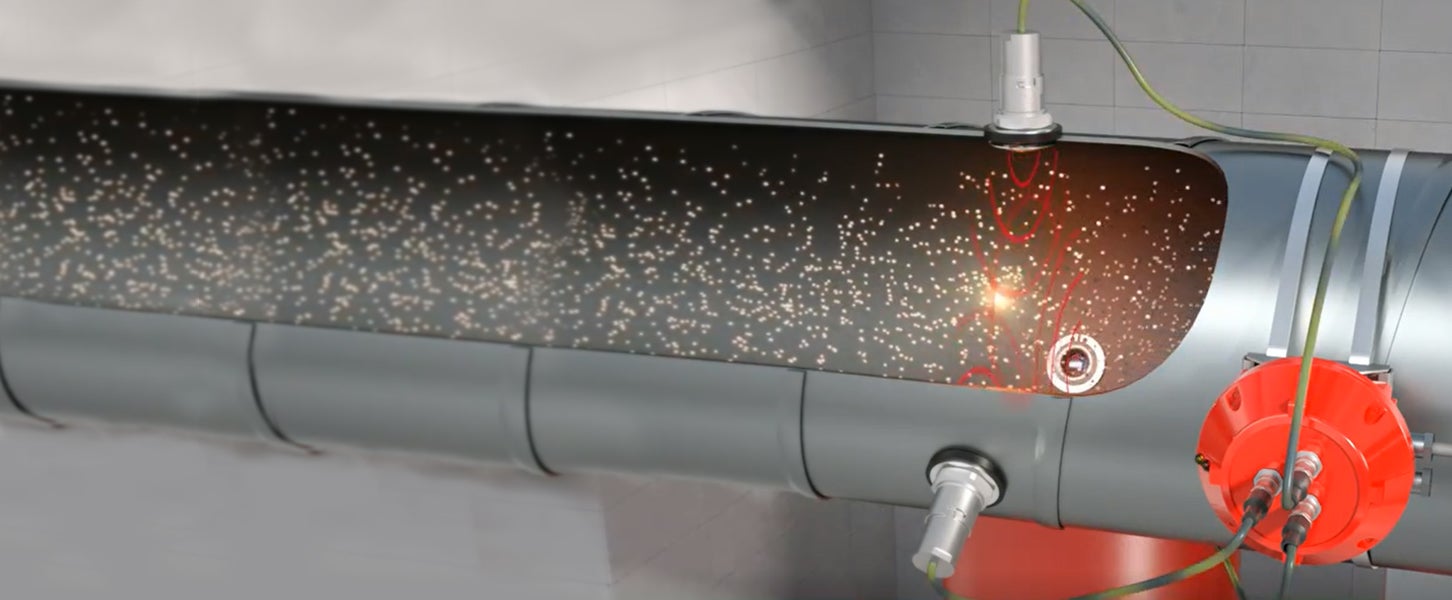

The FLAMEX system senses sparks and burning material. It then extinguishes it in milliseconds before it can become an ignition source for a fire or explosion. A minimal amount of water is used to eliminate down time and clean up.

The pneumatic conveying of combustible dusts carries inherent risks for dust fires and explosions. Processes involving grinding, cutting, sanding and drying often cause sparks. These are typically the ignition source for fires and explosions in facilities that handle combustible dusts. The FLAMEX system is specifically designed to address these hazards. It has proven to be a reliable, cost effective solution for the prevention of dust collector fires and explosions in a variety of industrial applications.

This simple and straightforward prevention approach minimizes or eliminates production interruption. The flexibility of the system allows its use with a variety of detection and suppression components. This facilitates its use in a number of customized system designs.

COMPONENTS

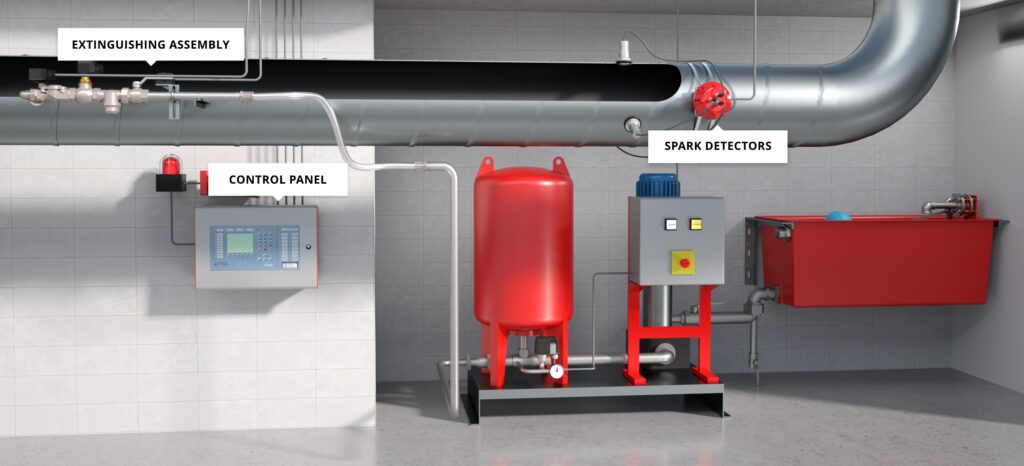

The basic system is typically comprised of three main components: a Control Panel, Spark Detectors, and an Extinguishing Assembly.

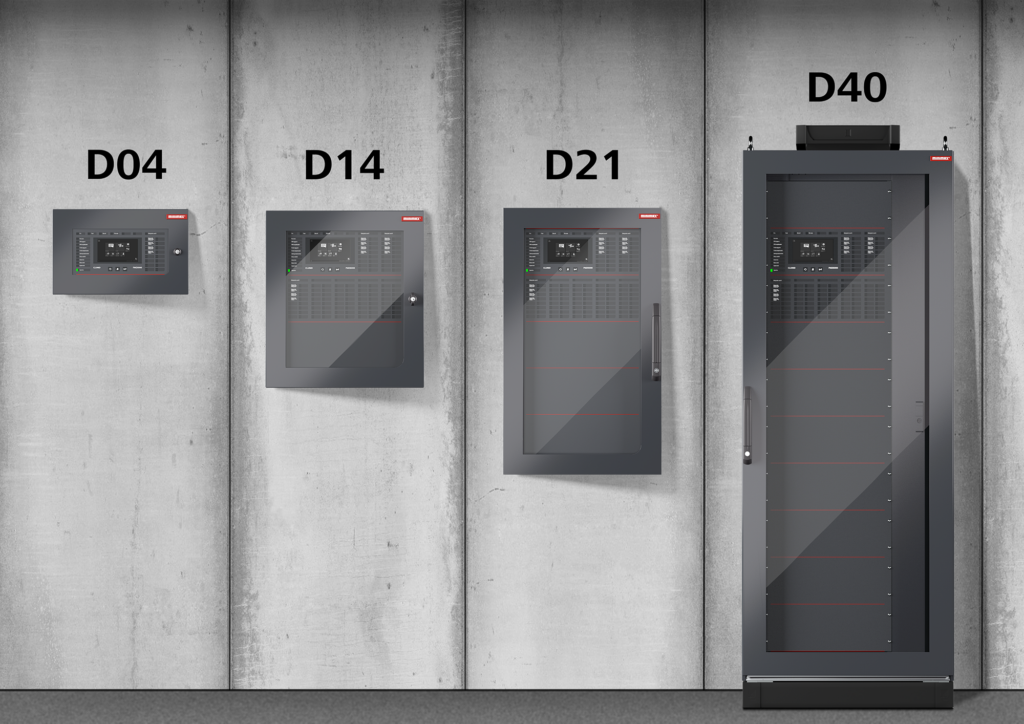

Control Panels

Control panels are sized based upon the requirements of the application. A number of models with various features are available. Panels can range from the most basic single zone console to sophisticated multi-zone panels with technologically advanced features. All are compatible with FLAMEX Detectors and Extinguishing Assemblies.

FLAMEX Inc. can assist you with the selection of the appropriate control panel to meet the requirements of your specific application.

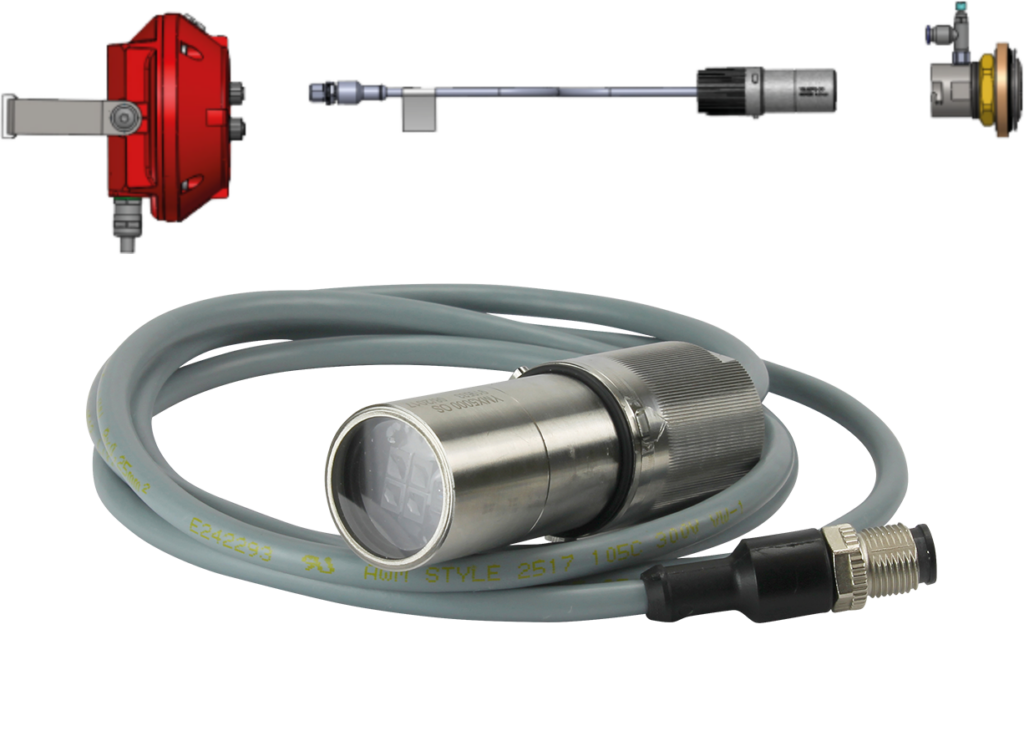

Detectors

Detecting a spark in a pneumatic material transport duct at speeds that often exceeds 5,000 feet per minute requires a very sensitive and very fast sensing device. FLAMEX Spark Detectors provide the sensitivity, speed, durability and reliability that such an application demands. Two or more spark detectors will be required to monitor a duct cross-section depending upon the size and configuration of the duct. These detectors are ideally mounted on a main section of ductwork downstream of any material input branch ducts and sufficiently upstream of the proper location for the extinguishing assembly to be installed. Upon detection, the detectors cause the system to activate thereby triggering the extinguishing device and causing the panel to go into an alarm state. The detectors automatically and immediately reset themselves so that they stand ready to detect any possible subsequent sparks.

Extinguishing Assembly

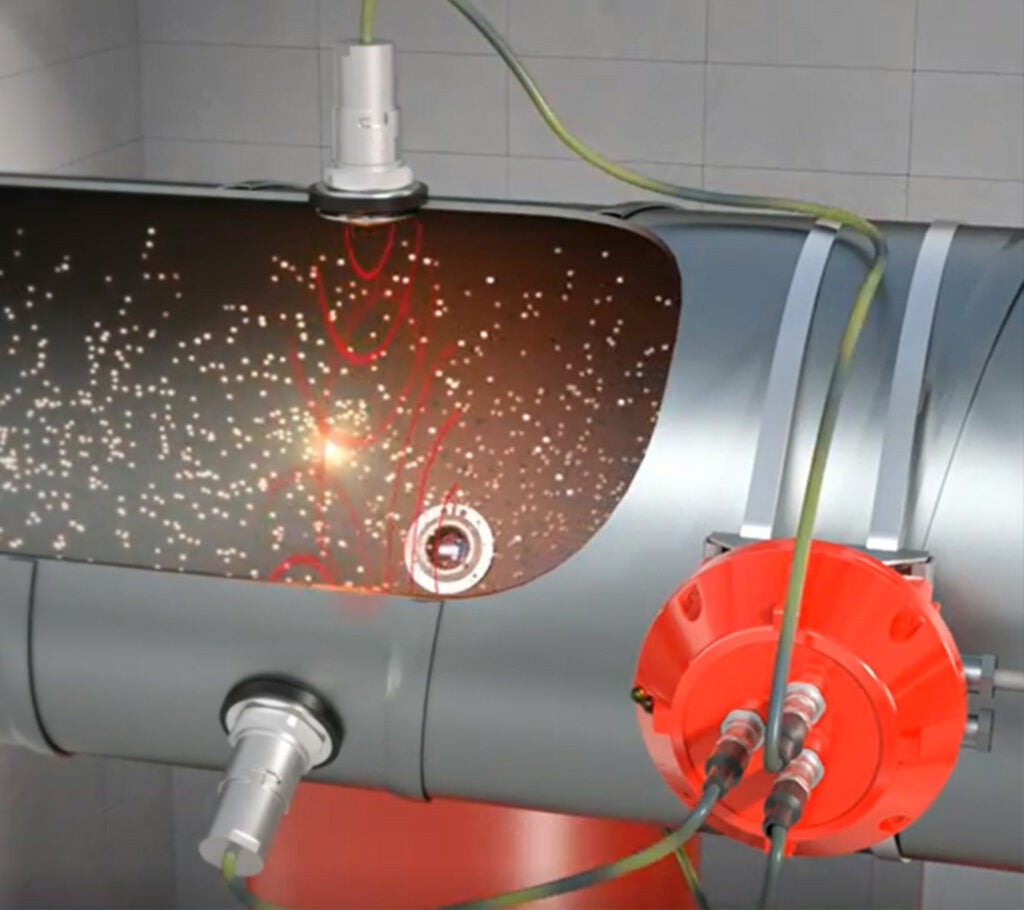

The Extinguishing Assembly is a pre-assembled device that mounts to the duct downstream of the detector location and upstream of the inlet to a dust collector. It is made up of a number of components outlined below.

The fast-acting solenoid valve reacts without delay upon activation. The specially designed stainless steel nozzle creates a 180 Degree water spray pattern effectively covering the duct cross section. This spray curtain is actualized inside the duct in less than 300 milliseconds and quenches the detected sparks as they pass through. The spray cycle time is pre-set and shuts off after the last spark has been extinguished to minimize the amount of water used during an activation.

Each system is custom designed to meet the protection requirements of each individual specific application.

HOW DOES A SPARK DETECTION & EXTINGUISHING SYSTEM WORK?

A fully automatic spark detection & extinguishing system consists of spark detectors, a control panel and an automatic extinguishing system as standard. If the spark detectors have detected sparks or hot particles in the conveyed material, they send a signal to the control panel. This then controls the solenoid valve of the automatic extinguishing system in the millisecond range. The extinguishing water releases into the conveying flow via patented self-closing nozzles. The glowing particles fly into the water veil built up by the nozzle. Immediately afterwards, the solenoid valve automatically closes again. At the same time, the alarm triggers.

WHAT WE DO

SPARK DETECTION & SUPPRESSION SYSTEM

MINIFOG WATER MIST SYSTEM

COMPONENTS

MXONE

HOW CAN WE HELP

Contact our support team for project inquiries, technical questions and service.