Dust explosion hazard

Hazard Recognition

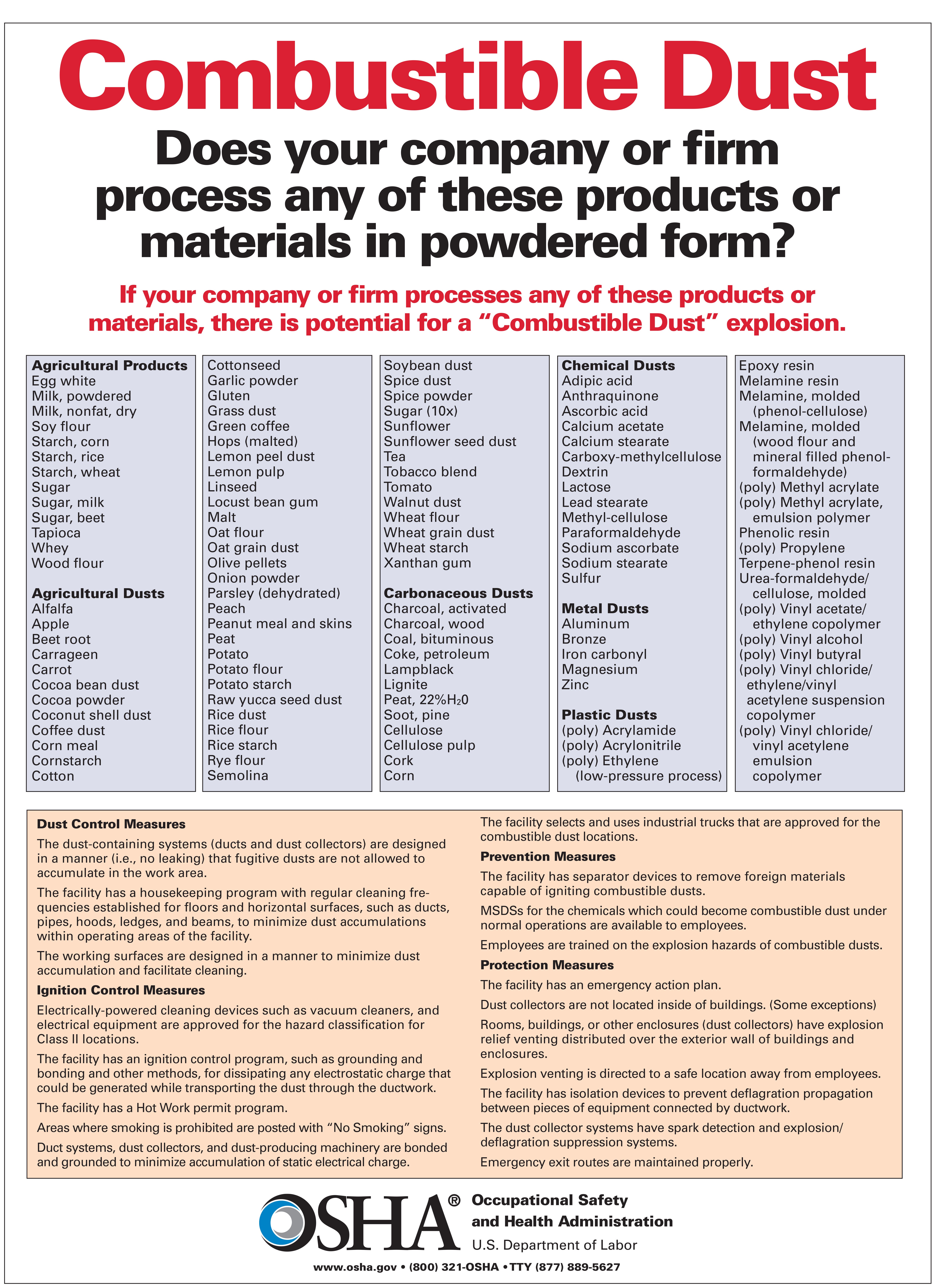

Facilities that create, handle, and collect combustible dusts as a result of their manufacturing processes face an inherent risk of fires and explosions. Once dust explosion hazards are recognized, effective mitigation strategies can be employed to prevent or attenuate incidences of dust fires and explosions that threaten lives, property, and business continuity.

The information below identifies some common risks and provides recent loss histories in industrial facilities that handle combustible dusts.

A combustible dust is any material (finely divided solid particles) that has the ability disperse in air and catch fire and explode when exposed to an ignition source. Combustible dust may include materials that are in the physical states of powders, flakes, fines, fibers, etc.

Combustible dusts can include:

- Most solid organic materials (such as sugar, flour, grain, wood, etc.)

- Carbonaceous materials (e.g., charcoal, soot)

- Textile fibres (e.g., cotton)

- Many metals, and

- Some nonmetallic inorganic materials.

Some of these materials are not “normally” combustible, but they can burn or explode if the particles are the right size and in the right concentration.

Therefore any activity that creates dust should be investigated to see if there is a risk of that dust being combustible. Dust can collect on surfaces such as rafters, roofs, suspended ceilings, ducts, crevices, dust collectors, and other equipment. When the dust is disturbed and under certain circumstances, there is the potential for a serious explosion to occur. The build-up of even a very small amount of dust can cause serious damage.

The basic requirements for a dust explosion to occur are that combustible dusts are suspended in air and are ignited. In practice, for a dust explosion to occur, a number of conditions must be met including:

- The dust must be combustible and release enough heat when it burns to sustain the fire.

- The dust must be capable of being suspended in air.

- The dust must have a particle size capable of spreading the flame.

- The concentration of the dust suspension must be within the explosible range.

- An ignition source must be in contact with the dust suspension.

- The atmosphere must contain sufficient oxygen to support and sustain combustion.

- There is a form of confinement or enclosure that allows pressure to build.

Source: Combustible Dust: OSH Answers, https://www.ccohs.ca/oshanswers/chemicals/combustible_dust.html, Canadian Centre for Occupational Health and Safety (CCOHS), Reproduced with the permission of CCOHS, 2022

HAZARD IDENTIFICATION

The importance of hazard recognition cannot be overstated. Unfortunately, in many industrial facilities the management and employees do not understand the risks under which they operate every day. It is crucial that the hazards associated with combustible dusts are recognized and addressed. In addition to the critical need for the protection of lives, property and minimization of operational downtime, there are legal and ethical considerations involved in maintaining a safe workplace for employees as stated in the OSHA General Duty clause.

OSHA General Duty Clause, OSH Act of 1970 SEC.5.

(a) Each employer — (1) shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees;

Violations of this provision are subject to citations and fines by the US Department of Labor.

-

5 Elements Required For An Explosion to Occur

It is possible that 4 of these elements may all be present at times within a typical dust collector operating under normal conditions. Under these conditions, should the concentration (MEC) and characteristics (particle size, dryness) of the dust constitute that it is deflagrable, all that is necessary for an explosion to occur is the introduction of a spark or glowing ember into this potentially dangerous environment.

-

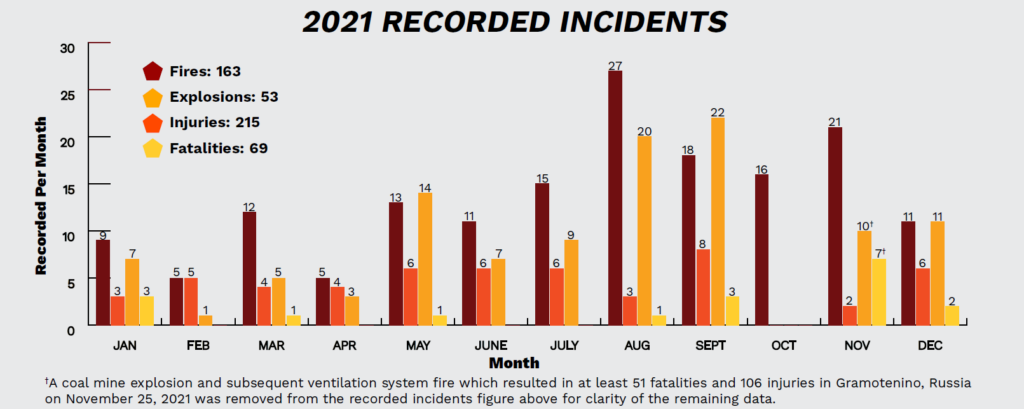

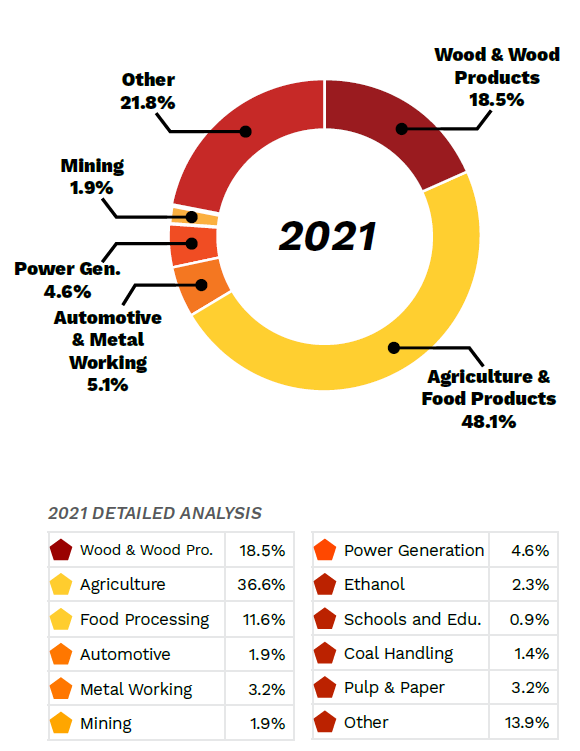

Recent Incident History of Fires and Explosions

The following information points to a number of recognized hazards based on loss histories and consensus data provided by members of the loss control community. This information is by no means comprehensive and is limited in scope to identify certain major risks inherent in facilities that handle combustible dust.

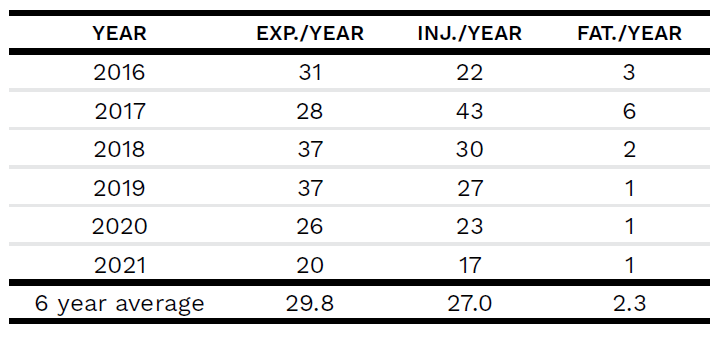

Loss history from dust explosions in the United States over the last six years is given in the following table.

Source: Cloney, Chris (2021). “2021 Mid-Year Combustible Dust Incident Report – Version #1” DustEx Research Ltd. Retrieved from http://dustsafetyscience.com/2021-Report

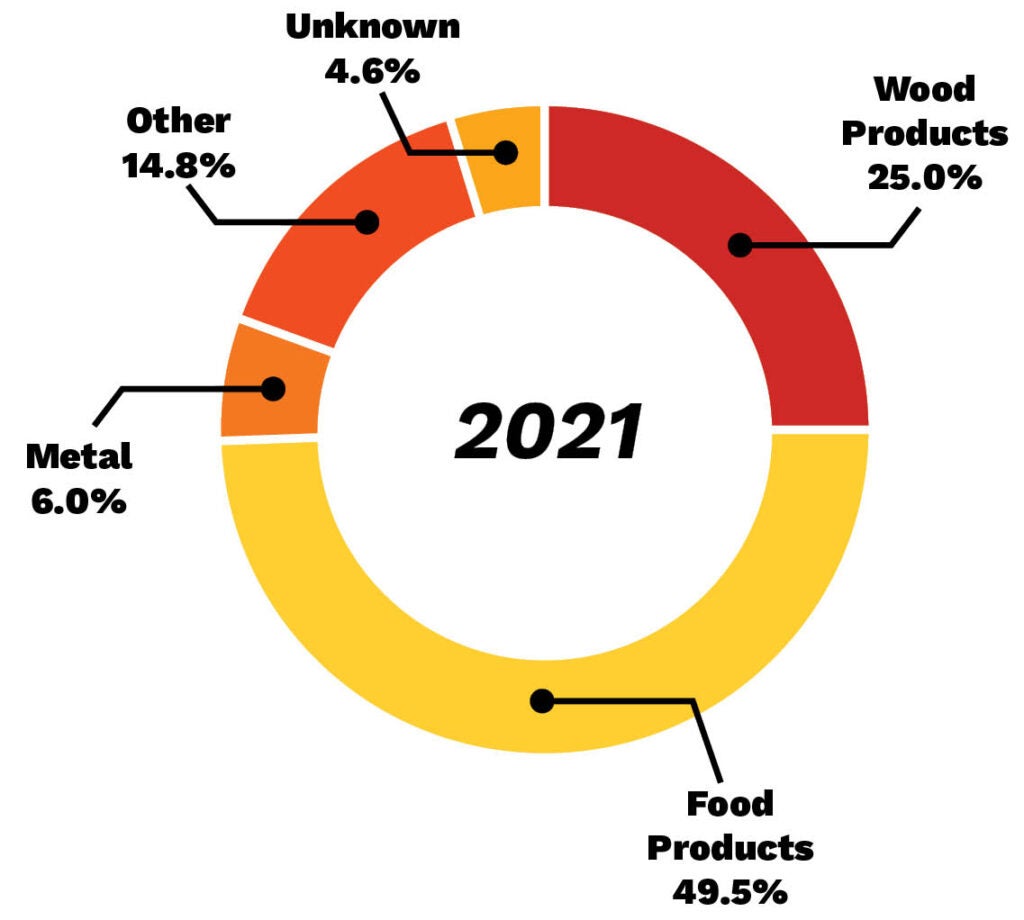

In addition to the data provided by Dust Safety Science above are the findings contained in a study which analyze data over a ten year period in an effort to identify key variables leading to fires an explosions in dust collectors. Among their findings they report that “Based on the collected data, the quantitative analysis showed that the most frequent type of dust that was involved in the explosions during the last 10 years was wood dust. It is also the type of dust with the highest number of injuries and the most extensive property damages. The qualitative analyses showed that friction sparks and self-heating are the primary causes of ignition, whereas ineffective housekeeping and design problems of the dust collection system are the biggest contributing factors for the occurrence of the explosion events.”

– Variable impacting the probability and severity of dust explosions in dust collectors, Fire Protection Research Foundation Report, December 2020

Dust Hazard Analysis (DHA)

Owners/operators of a facility where materials determined to be combustible or explosible are present in an enclosure are responsible for obtaining a Dust Hazard Analysis (DHA) in accordance with NFPA 652 Chapter 7.

A DHA is written document that is prepared by a qualified individual to identify specific hazards in your facility and to provide prescriptive measures to be taken to address those identified hazards. The DHA is to be reviewed and updated every 5 years.

DUST COLLECTION SYSTEMS

It is not at all surprising that Dust Collectors are consistently reported to be the number one piece of equipment most associated with dust fires and explosions. Indeed, the nature and process of dust collection and air filtration in many industries create an environment for these incidences to occur.

The dangers associated with wood dust collection is also well recognized in the NFPA Standard 664 for woodworking facilities as it is cited that “A fire hazard shall be deemed to exist in the system wherever dry wood particulate is collected or conveyed…” NFPA 664 (2020) 9.3.3.1.4

Although the incidences of explosions are less frequent that those of fires, an explosion is more likely to happen as a result of an ongoing fire in the baghouse.

”Dust Collection Systems are designed to remove dust, conveying it in an airstream, through ducts, to a point where the particulate matter is separated from the airstream.” “If the dust is combustible, the potential for fires and explosions within these systems is very high… In a recent 15-year period, 79% of all combustible dust losses reported by FM Global clients were related to dust collectors.”

From the FM Global Property Loss Prevention Data Sheet 7-73 Dust Collectors and Collection Systems (July 2020) ©2020 Factory Mutual Insurance Company. All rights reserved.

-

Some Basic Prevention Measures

Having recognized that dust accumulations and the collection and handling of these dusts in industrial facilities carry with them the dangers and risks associated with potential ignition it is the responsibility of the owner/operators to address these hazards in able to maintain a safe work environment.

The measures listed below are a few steps that can be taken in an effort to limit the possibility of experiencing a devastating incident in your facility. These are by no mean comprehensive but are some practical, proven practices and strategies to reduce the potential consequences that can be caused by ignition. Again, we strongly recommend that a DHA be conducted by a qualified individual that can provide more specific and comprehensive prescriptive measures for prevention and protection.

- Initiate a safe, continual housekeeping process to prevent dust layer build up on all surfaces

- Locate Dust Collectors outdoors

- Ensure that dust collection systems are properly designed and sufficient conveying velocities are maintained

- Provide proper explosion venting on dust collectors and bins

- Provide Safety Training for personnel and maintain written procedures and policies

- Provide regular preventative maintenance on process machinery

- Install and maintain automatic fire protection systems and explosion prevention systems

There are a number of automatic fire and explosion protection systems that can be employed in the suppression of dust collector fires and explosions. These include explosion suppression systems, chemical isolation and sprinkler systems among others. Each can play an important roles in meeting the requirements of a specific protection application but no one type of system can provide complete protection so each should be considered as individual components of an overall protection design.

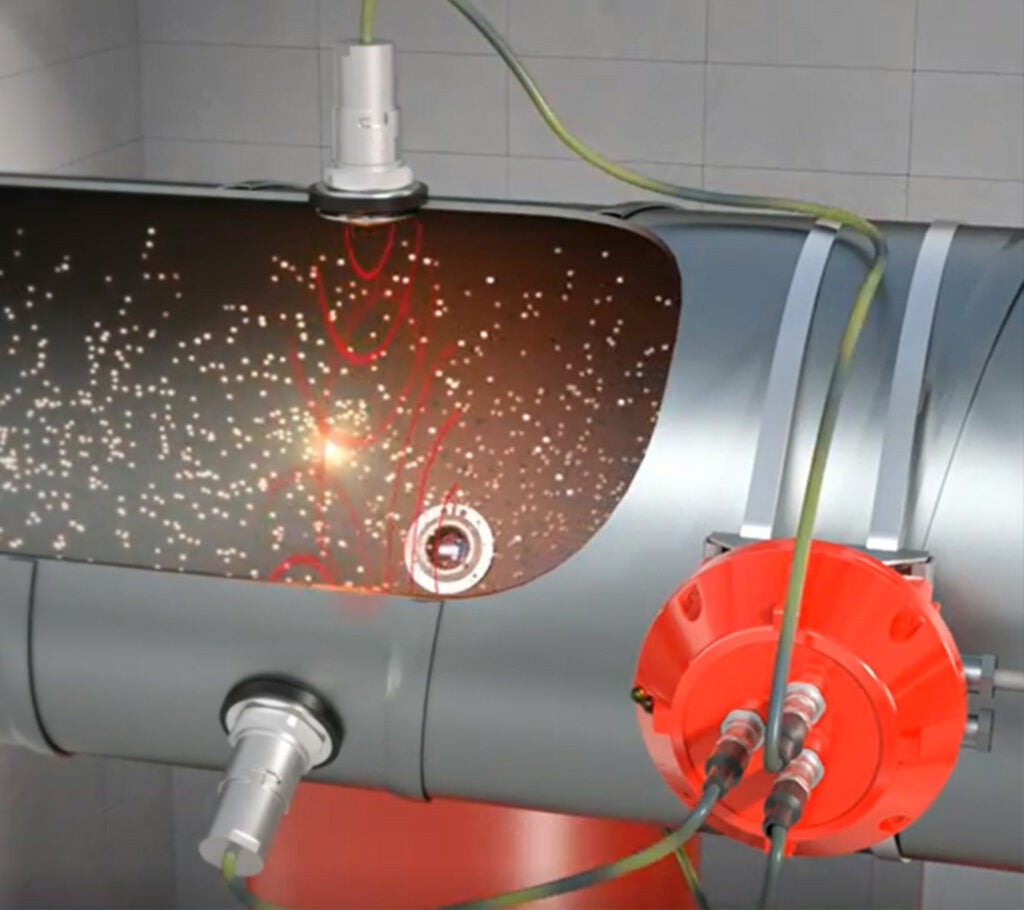

In many applications where the dust material is not water reactive, Spark Detection and Extinguishing Systems can provide the unique advantage of PREVENTION by the elimination of the potential source of ignition. Prevention of an incident is often much easier and more cost effective than having to address a fire or explosion in progress and therefore can represent a preferable solution to these problems that are common to many industrial facilities that utilize dust collection and air filtration systems.

-

Resources

Below are some links to organizations involved in the prevention of dust fires and explosions which can provide additional information and resources.

WHAT WE DO

SPARK DETECTION & SUPPRESSION SYSTEM

MINIFOG WATER MIST SYSTEM

COMPONENTS

MXONE

HOW CAN WE HELP

Contact our support team for project inquiries, technical questions and service.