Add explosion safety

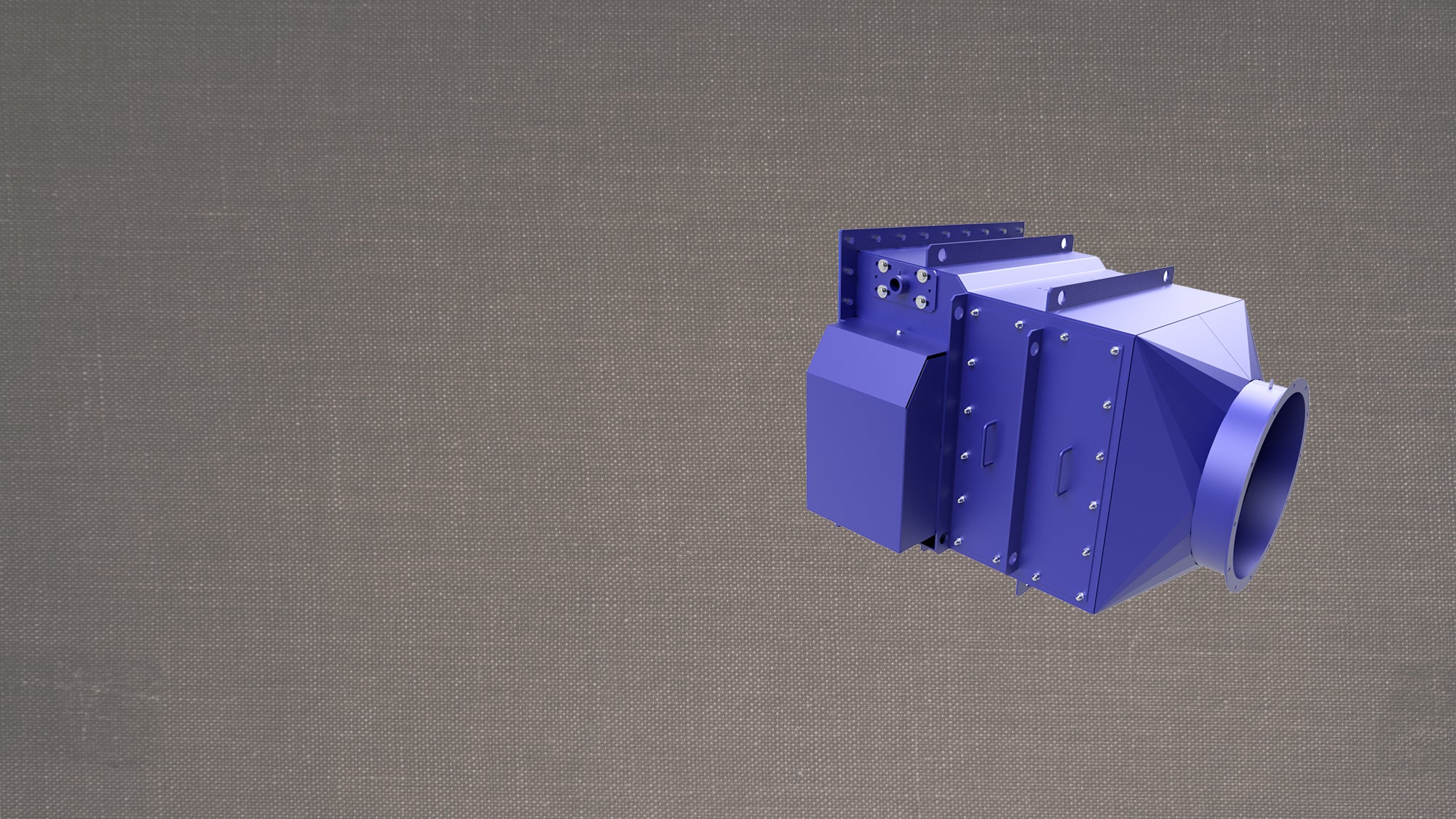

Explosion Isolation Flap

An Explosion Isolation Flap (EIF) is a passive isolation device used to prevent a deflagration from propagating back upstream through material handling ductwork in the event of a dust collector explosion.

An Explosion Isolation Flap is installed on the ductwork upstream of a dust collector. The manufacturer will have installation requirements specifying the minimum and maximum distance from the dust collector inlet to locate the unit. The system components of a Spark Detection and Extinguishing System should be installed upstream of the EIF location.

The flap on an EIF is held open by the normal process airflow. A pressure wave from an explosion in the collector forces the flap down and prevents the flame from passing further upstream. The resulting pressure build up is vented through the explosion vents in the dust collector. Therefore, it is crucial that Explosion Isolation Flaps are used in application where the dust collector is properly vented.

The Kst value of the material conveyed must be considered in selecting the appropriate Explosion Isolation Flap. Available models are constructed to withstand different pressure levels and are rated accordingly.

Some manufacturers of EIFs offer units that can be used in both positive and negative (push-pull) pressure applications.

When purchasing an Explosion Isolation Flap, it is important to consider the amount of static pressure loss that will incur in the airstream after installation. The amount of drag on the air flow may vary considerably among available units.

NFPA 69 provides important information concerning the requirements of Explosion Isolation Flaps (or Flow-Actuated Flap Valves) to meet recognized industry standards. Third party certification and a latching mechanism which initiates an automatic shutdown of the protected area are among those requirements.

WHAT WE DO

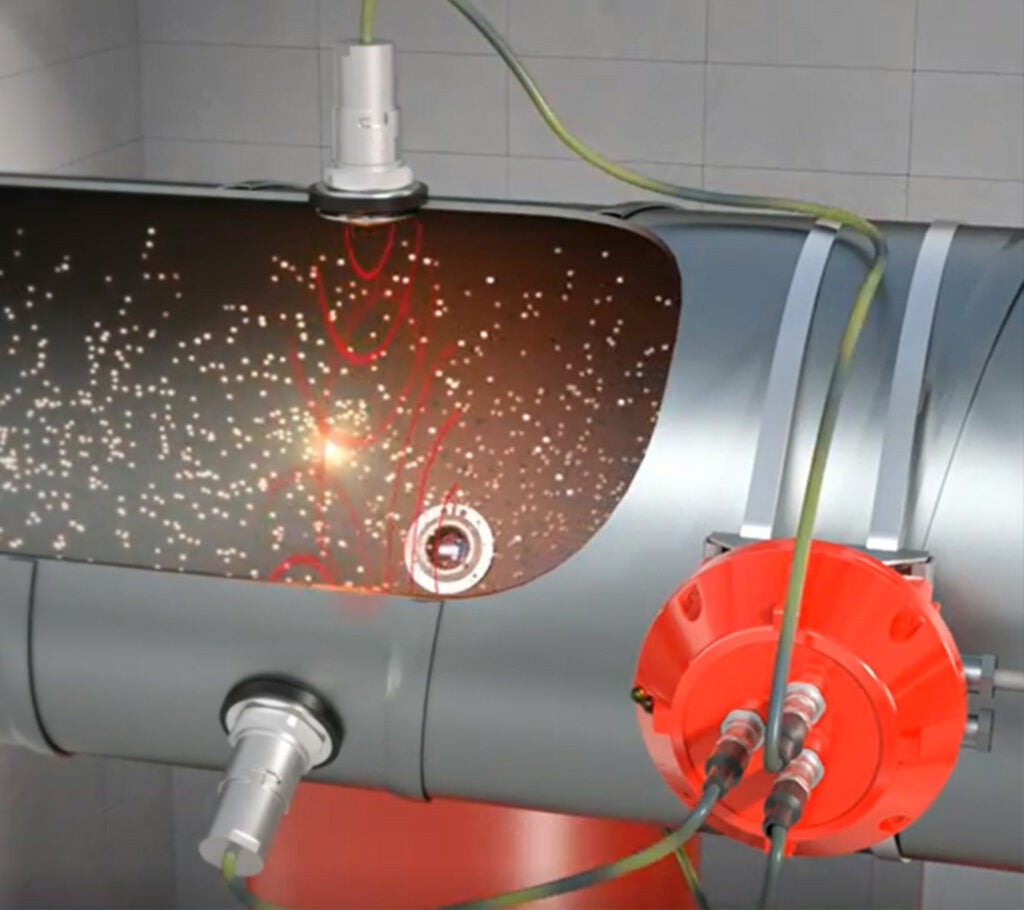

SPARK DETECTION & SUPPRESSION SYSTEM

MINIFOG WATER MIST SYSTEM

COMPONENTS

MXONE

HOW CAN WE HELP

Contact our support team for project inquiries, technical questions and service.