Add Industrial Fire Prevention

About Us

WHO WE ARE

FLAMEX Inc. is a leading supplier of customized industrial process fire prevention and protection equipment. We specialize in the protection of facilities that handle combustible dusts that utilize pneumatic dust collection and air filtration systems.

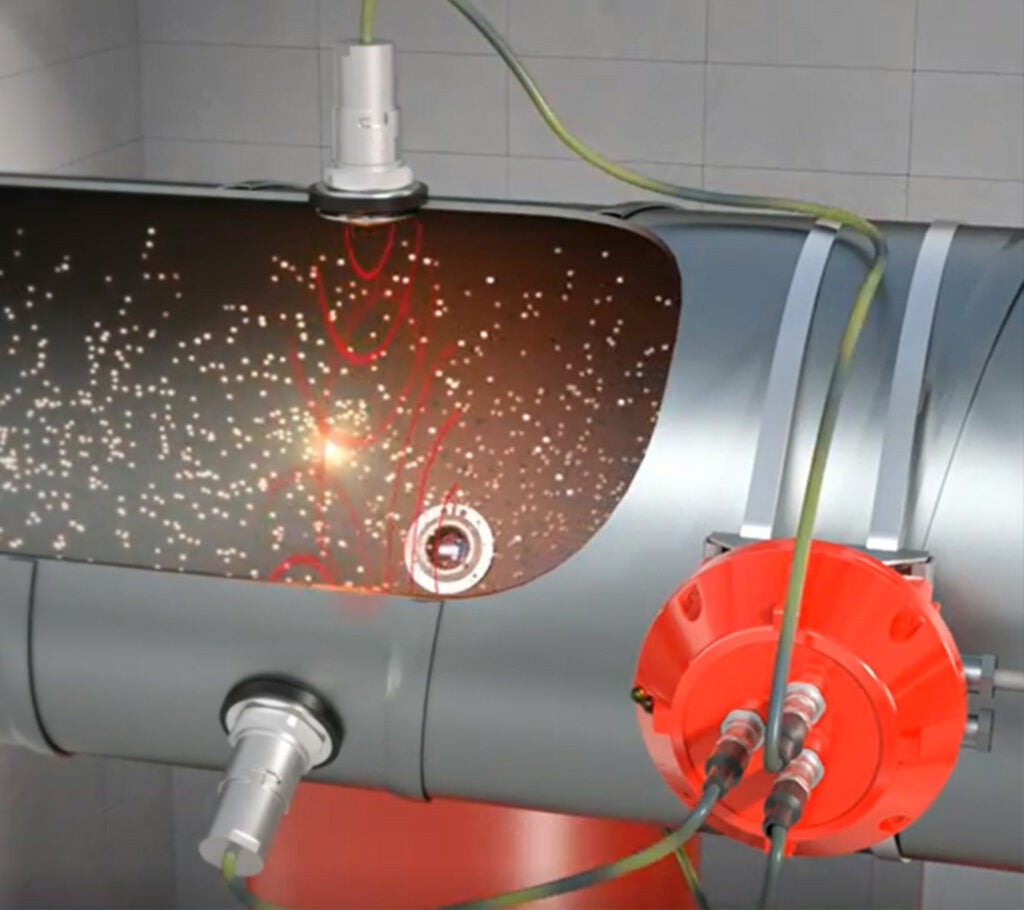

To combat the common problem of dust collector fires and explosions, our company pioneered a new technology in North America. The FLAMEX Spark Detection and Extinguishing System was introduced in 1977. It soon became the first system of its type to gain a Factory Mutual Approval. Since that time, thousands of FLAMEX systems have been installed in numerous industries across North America and beyond.

FLAMEX Inc. has the unique advantage of being the only North American supplier of Spark Detection and Extinguishing Systems and related products that is part of a major global fire protection equipment manufacturing organization. Our parent company MINIMAX GmbH has over 110 years of experience in industrial fire protection and a commercial presence that extends around the globe. With its acquisition of Viking Sprinkler Corporation in November 2009, MINIMAX has become a world leader in fire protection technologies. The organization now has approximately 9,500 employees and 1.9 Billion Euro in annual turnover.

Our name is often considered synonymous with Spark Detection Systems. FLAMEX Inc. also offers a variety of other related protection systems and products. The MINIFOG ProCon Fine Water Mist System and the MXOne Firefighting Turbine are just a few of them.

OUR CAPABILITIES

Our capabilities include the design, supply and service of complete industrial fire protection systems.

The experience, technical expertise and resources possessed by our ISO 9001 manufacturing partner affords FLAMEX the unique ability to offer a much broader product line. We offer more comprehensive protection solutions to address the requirements of varied industrial applications than would a typical vendor. While there are some similar products, the variety, quality, features, service and experience that FLAMEX offers cannot be paralleled by others.

OUR PHILOSOPHY

We provide engineered systems, customized to meet the requirements of each application as well as the individual customer’s needs. We believe that fire protection systems installed to protect people and property are too important to be supplied as a collection of commoditized components.

The appropriate detection component for each application is selected, rejecting the “one size fits all” concept. Different processes within a production stream constitute different detection applications. We select the detector best suited to provide the most effective and reliable detection.

At FLAMEX, we continually strive to provide the best value in the marketplace, not necessarily the lowest price. Our emphasis is on providing quality systems, reliable and dependable giving our customers years of valuable service.

OUR HISTORY

The company was originally founded in 1971 when the East Asiatic Company, a Danish multi-national corporation, decided to establish a firm in the U.S. to supply Danish dust collectors manufactured by Moldow Ltd. Mr. Ole Sorensen, an EAC employee, was selected to head up this endeavor. He chose Greensboro because of its proximity to the furniture industry and its quality of life.

The company was originally known as Moldow Dust Control Inc. (a joint venture between EAC and Moldow). Throughout the seventies the company grew as sales continually increased. As our experience in dust collection grew, we saw that a major safety hazard existed in the processes of dust extraction and air filtration. Dust fires and explosions were very common to the woodworking industry, which included a majority of our customers. In an effort to combat this plague to the industry, company management sought out a solution.

In 1975 it was discovered that a German Company, Preussag MINIMAX, was developing a system designed to specifically address this problem. Company management knew this would be a perfect complement to our product line and pursued a relationship. Shortly thereafter, MINIMAX granted a North American distributorship of its Spark Detection and Extinguishing System to Moldow Dust Control. It was decided that this system would be marketed in the U.S. under a brand name of FLAMEX. Introduced to the U.S. in 1978 at a Louisville woodworking exhibition, FLAMEX won the coveted Challenger Award for the best new product in the Woodworking Industry. FLAMEX became the first system of its type to gain Factory Mutual Approval and quickly became the industry standard.

In 1993, certain assets of EAC Engineering USA were purchased by Mr. Ole Sorensen, creating a new company, FLAMEX Inc., to emphasize the brand name of our principal product. The company prospered under Ole’s ownership and direction. Ole sold the company in 2005 to our longtime supplier, MINIMAX. He continued to lead the company until his untimely death in January 2009. Today, the company maintains the FLAMEX name. We are part of a large multi-national organization that is among the major global players in industrial fire protection equipment

OUR COMMITMENT

For over 40 years, our company has been committed to protecting the lives and property of our customers. The excellent reputation we enjoy speaks for the quality of our products and the integrity of our staff.

We appreciate your interest in our company and thank you for visiting our web site. We invite you to contact us concerning how we can be of assistance to your organization.

WHAT WE DO

SPARK DETECTION & SUPPRESSION SYSTEM

MINIFOG WATER MIST SYSTEM

COMPONENTS

MXONE

CAREERS

We seek to employ individuals with commitment, competency and integrity that wish to pursue an interesting and challenging career.